Why Trusting Sikorsky Parts Distributors is Vital for Security and Efficiency

Why Trusting Sikorsky Parts Distributors is Vital for Security and Efficiency

Blog Article

The Importance of Compatibility and Security Attributes in Sikorsky Components Selection

In the realm of aeronautics, the option of Sikorsky components demands a thorough concentrate on compatibility and safety and security functions, as these aspects are paramount to both operational performance and the guarding of human life. Ensuring that parts work decreases the likelihood of mechanical failures, while integrated security functions add dramatically to system resilience in adverse conditions. This discussion highlights the criticality of adhering to recognized regulative requirements and finest methods, yet it increases a crucial inquiry: what are the possible consequences of disregarding these essential factors to consider in the components option procedure?

Comprehending Compatibility in Air Travel Components

In the realm of air travel, guaranteeing compatibility among components is paramount for functional performance and safety and security. The complex systems within airplane need that every part, from engines to avionics, job flawlessly with each other. Compatibility includes not only physical measurements yet likewise material homes, performance specifications, and useful attributes. When choosing Sikorsky parts, it is vital to analyze whether they satisfy the recognized standards and requirements for the certain aircraft version.

Appropriate compatibility mitigates the danger of malfunctions and improves the long life of the aircraft. Designers should take into consideration different variables, such as load-bearing capabilities, ecological conditions, and compatibility with existing systems. For circumstances, a rotor blade created for a specific helicopter design must be matched with the right center and drive system to guarantee optimum performance.

Failing to guarantee compatibility can cause functional disturbances, raised upkeep prices, and safety and security dangers. sikorsky parts distributors. Thorough analysis procedures, consisting of thorough documentation and testing, are crucial in the selection of aviation parts. By prioritizing compatibility, stakeholders can promote a culture of safety and reliability within the aeronautics sector, inevitably adding to effective objectives and the wellness of travelers and staff alike

Secret Safety Features to Consider

Safety and security attributes play an essential duty in the option of Sikorsky parts, directly influencing the integrity and performance of aircraft procedures. When reviewing components, a number of essential safety attributes necessitate interest to guarantee optimal efficiency and danger mitigation.

Third, efficiency metrics such as lots ability and tiredness resistance must be examined to make sure that parts can deal with operational needs without endangering safety and security. 4th, the existence of advanced monitoring systems can give real-time information on part performance, allowing for aggressive upkeep and timely interventions.

Last but not least, conformity with air travel standards and laws is non-negotiable. Making certain that components meet or exceed industry safety and security accreditations guarantees adherence to ideal methods. By concentrating on these vital security features, Sikorsky drivers can improve the safety and stability of their aircraft, inevitably adding to safer aeronautics procedures.

Threats of Incompatible Components

Utilizing incompatible components in Sikorsky aircraft can cause significant functional risks that endanger both security and efficiency. The integration of parts that do not meet rigorous compatibility requirements can cause mechanical failures, lowered reliability, and possibly catastrophic mishaps (sikorsky parts distributors). Such failings Read Full Article typically arise from mismatched requirements, including inaccurate measurements, materials, or design resistances that might not straighten with the airplane's original design parameters

Furthermore, using inappropriate parts can interrupt essential systems, such as avionics or propulsion, causing a loss of control or decreased maneuverability throughout flight. This not only threatens the crew and guests however also poses dangers to ground workers and onlookers. Additionally, the ramifications of making use of incorrect components prolong past immediate safety and security problems; they can additionally lead to costly repairs, extended downtime, and increased liability for operators.

Inevitably, ensuring that all parts are suitable and comply with the supplier's specs is crucial for keeping the honesty of Sikorsky airplane. An aggressive technique to components choice is important to reduce these risks, ensuring optimal performance and safeguarding the lives of all those on board.

Governing Requirements and Conformity

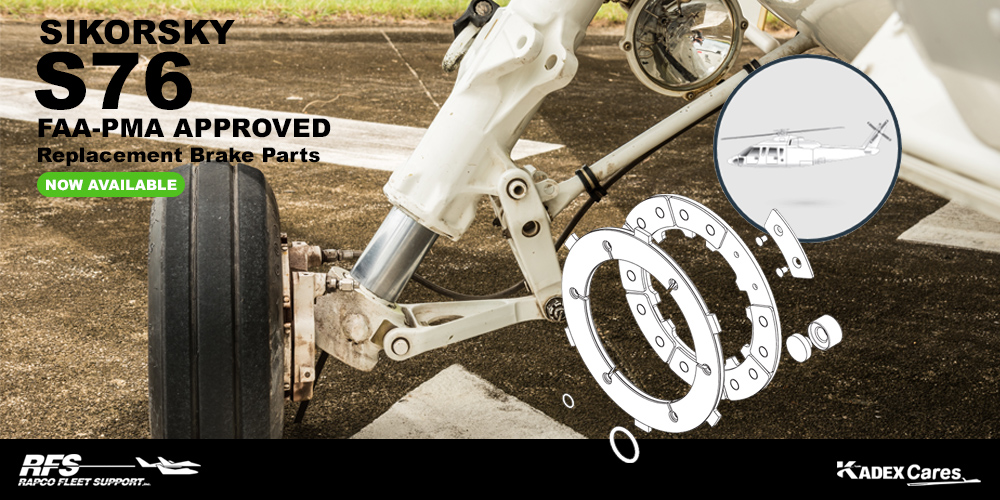

When picking components for Sikorsky aircraft,Making certain conformity with regulatory criteria is critical. Regulatory bodies such as the Federal Air Travel Administration (FAA) and the European Union Aeronautics Security Agency (EASA) develop stringent standards that govern the layout, manufacturing, and my explanation upkeep of aviation parts. Adherence to these standards is essential to guaranteeing the safety and security and dependability of airplane operations.

Conformity with regulatory standards not just safeguards the lives of passengers and team but likewise shields the integrity of the airplane itself. Parts should undertake rigorous screening and qualification processes to verify they fulfill performance and security standards. This includes examining products, design specs, and making techniques.

Additionally, preserving documents that demonstrates compliance is necessary for accountability and traceability. In case of assessments or audits, having thorough records guarantees that all parts fulfill the necessary regulatory demands.

Choosing components that are licensed and certified with established regulatory standards assists alleviate threats associated with non-compliance, such as operational downtimes and legal repercussions. Eventually, prioritizing regulative compliance in parts choice reinforces Sikorsky's commitment to quality in air travel safety and performance.

Best Practices for Components Option

Efficient parts option is an important process that straight influences the performance and integrity of Sikorsky aircraft. Thorough research study on each part's requirements, including product residential properties and compatibility with existing systems, ought to be performed.

Next, focus on sourcing parts from reliable suppliers who adhere to market criteria and have a proven record of reliability. This step is crucial to maintaining security and ensuring regulative conformity. Additionally, carrying out a robust verification procedure, consisting of evaluations and screening, can help confirm that chosen components meet all operational needs.

Furthermore, preserve detailed documentation of all parts and procedures to facilitate traceability and responsibility. This technique not just aids in compliance however additionally sustains more efficient maintenance and prospective troubleshooting in the future.

Last but not least, take part in continuous training and development for workers included in components option to remain educated about the most recent improvements and finest techniques in the sector (sikorsky parts distributors). By adhering to these ideal techniques, Sikorsky airplane drivers can boost safety, integrity, and overall efficiency

Conclusion

In recap, the relevance of compatibility and safety features in Sikorsky components selection is paramount for making certain operational efficiency and airplane safety. Correct compatibility evaluation mitigates the threats of mechanical failures, while essential security features boost system dependability.

Report this page